The global manufacturing landscape is changing rapidly. Rising raw material costs, growing environmental awareness, and stricter regulations on plastic waste disposal are reshaping how businesses operate. At the center of this transformation lies the plastic granulator machine, a crucial piece of equipment that turns plastic scrap into reusable pellets. By reducing waste and enabling a circular economy, plastic granulators are helping companies balance profitability with sustainability.

Table of Contents

Why Plastic Granulators Matter

Plastic is everywhere: in packaging, automotive parts, construction materials, consumer electronics, and more. While plastics bring convenience and durability, they also generate large volumes of post-industrial and post-consumer waste. Without effective recycling, this waste ends up in landfills or the ocean, creating severe environmental issues.

A plastic granulator solves this problem by breaking down discarded plastic materials—such as films, bottles, and injection-molded parts—into uniform pellets that can be fed back into production lines. This process reduces the demand for virgin raw materials, cuts costs, and minimizes the environmental footprint of manufacturing.

How Plastic Granulators Work

A plastic granulator machine uses sharp rotating blades to cut plastic waste into small pieces. The crushed material is then filtered, cooled, and dried before being processed into pellets. These pellets can later be melted and reshaped into new products, creating a closed-loop production system.

Modern granulators are designed for efficiency and durability. Features such as advanced cutting chambers, noise-reduction technology, and automated feeding systems ensure continuous operation with minimal downtime.

Types of Plastic Granulators

Different industries require different solutions, and manufacturers can choose from several types of granulators depending on their needs:

- Low-Speed Granulators – Ideal for recycling sprues and runners directly beside injection molding machines. They operate quietly and produce minimal dust.

- High-Speed Granulators – Designed for high-volume production facilities that process larger quantities of plastic scrap.

- Water-Cooled Granulators – Prevent overheating when processing heat-sensitive materials such as LDPE or PET.

- Air-Cooled Granulators – Commonly used in facilities with limited access to water systems.

- Heavy-Duty Granulators – Built for recycling bulky materials such as pipes, sheets, or thick-walled components.

Each type has its own advantages, and selecting the right one depends on factors like throughput requirements, material type, and energy efficiency goals.

Applications Across Industries

Plastic granulators play a vital role in multiple industries:

- Packaging: Recycling plastic films, stretch wraps, and containers for reuse in new packaging solutions.

- Automotive: Processing bumpers, dashboards, and interior components into pellets for secondary applications.

- Construction: Recycling pipes, insulation materials, and sheets for cost-effective building products.

- Consumer Electronics: Repurposing plastic housings from appliances, TVs, and mobile devices.

- Agriculture: Reusing discarded mulch films, irrigation pipes, and greenhouse coverings.

By enabling material recovery, granulators reduce overall production costs and strengthen sustainability efforts.

Economic and Environmental Benefits

- Cost Savings – Using recycled pellets significantly lowers material costs compared to virgin plastics.

- Waste Reduction – Scrap material that would otherwise be discarded is given a second life.

- Energy Efficiency – Recycling plastics often consumes less energy than producing new materials.

- Regulatory Compliance – Many governments encourage or mandate plastic recycling, making granulators an essential investment.

- Brand Image – Companies that embrace recycling enhance their reputation and appeal to eco-conscious customers.

Plastic Granulator vs. Traditional Recycling Methods

Traditional recycling often involves collecting and transporting waste to centralized facilities. This adds logistics costs and delays in material reuse. In contrast, having an in-house plastic granulator machine allows manufacturers to recycle immediately at the source. This reduces dependency on external suppliers, lowers carbon emissions from transport, and ensures a steady supply of raw material.

Key Features to Look for in a Plastic Granulator

When investing in a granulator, businesses should consider:

- Cutting Chamber Design – Determines efficiency and uniformity of granules.

- Energy Consumption – Energy-efficient models reduce operational costs.

- Durability – High-quality steel blades and robust construction extend machine lifespan.

- Noise Control – Essential for improving working conditions in factories.

- Automation – Features like auto-feeding and self-cleaning reduce labor intensity.

- After-Sales Support – Reliable service ensures long-term performance.

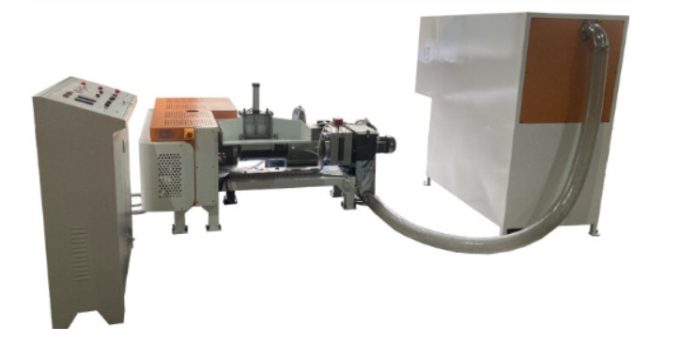

Case Example: Wintech Plastic Granulators

Wintech specializes in manufacturing advanced plastic granulator machines designed to meet global industry standards. Their machines combine precision cutting with high durability, making them suitable for packaging manufacturers, recycling plants, and large-scale industrial users.

One of Wintech’s most notable strengths is their focus on customization. Whether clients require high-speed solutions or energy-efficient models, Wintech offers flexible configurations tailored to specific needs. This ensures that businesses not only recycle effectively but also maximize their return on investment.

Future Outlook for Plastic Granulators

The demand for recycled plastics is projected to grow significantly over the next decade. As circular economy initiatives gain momentum, the role of plastic granulators will become even more central. Future innovations may include AI-driven monitoring systems, IoT-enabled performance tracking, and greater integration with smart factory setups.

Businesses that invest in this technology today will be better positioned to stay ahead of competitors while meeting regulatory and customer demands.

Conclusion

The plastic granulator machine is no longer just an optional tool—it is a strategic necessity for modern manufacturers. By transforming waste into valuable resources, it addresses both environmental challenges and economic pressures.

From packaging to automotive and beyond, plastic granulators empower industries to adopt sustainable practices without sacrificing efficiency. For companies seeking to reduce costs, minimize waste, and enhance their green credentials, investing in a high-quality granulator is the way forward.

Explore advanced granulator solutions at https://www.wintechmc.com and take the first step toward a more sustainable, profitable future.